hankyoreh

Links to other country sites 다른 나라 사이트 링크

S. Korean batteries companies expanding global production capacity

South Korean companies are racking up investment and orders in the global battery market, which is expected to experience rapid growth amid an increase in electric vehicles. SK Innovation and LG Chem, which are currently embroiled in a conflict over violations of business secrecy, made respective announcements on May 15 of a plan for investing in the construction of a new battery production plant in China and an order for a project involving the Swedish automaker Volvo.

In a board of directors’ meeting the day before, SK Innovation decided to invest 579.9 billion won (US$487.6 million) in expanding its Chinese battery production base. The investment is to be used to fund construction for a new production base to join the current factory in Changzhou. Groundbreaking for the Changzhou factory, with annual production of 7.5GWh (equivalent to 250,000 electric vehicles), took place in August of last year in collaboration with China’s Beijing Automobile Works (BAW) and Beijing Electronics.

“We decided to make an additional investment to seize an advantage in the rapidly growing electric vehicle battery industry,” explained an SK Innovation official.

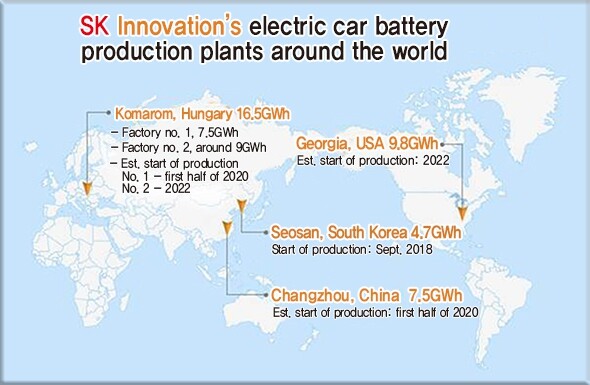

SK Innovation has been steadily building its global production capacity since beginning construction in March 2018 on an inaugural plant in Hungary. Construction on a second Hungarian factory was launched last February, and a groundbreaking ceremony was held in March for a factory in the US state of Georgia. Once the factories are completed, the company is expected to have a guaranteed production capacity of 40GWh by 2022. It also plans to continue building and expanding bases to ensure 60GWh in production capacity by 2022. As of late March, its cumulative order balance stood at 430GWh – 13 times its late 2016 level.

The same day, LG Chem was selected alongside China’s CATL as a final electric vehicle battery supplier for Volvo’s Polestar, which declared a halt to production of “new models” operating purely with internal combustion engines. Polestar is a high-performance electric vehicle brand launched by the Volvo Group in 2017.

The question of which global battery company Volvo would select as a supplier had previously been a subject of intense industry interest. It was an opportunity to supply batteries over the long term for use in Volvo’s third-generation electric vehicle platform, as opposed to batteries for one particular lineup. A platform is a vehicle body framework that can be applied with different electric vehicle models.

LG Chem has been working to build production bases in South Korea, the US, China, and Poland. Its electric vehicle battery order balance was announced at 110 trillion won (US$92.51 billion).

“We plan to lead the market with an overwhelming competitive edge as we enter the electric vehicle era in earnest,” said Kim Jong-hyeon, who heads LG Chem’s electric battery project headquarters.

On the same day that they announced their investment and order plans, the two companies were also girding for a legal battle in the US. Industry observers said the conflict arose when LG Chem – which has been moving to counter SK Innovation’s collaboration with Volkswagen – filed suit against SK Innovation, claiming violation of business secrecy.

By Choi Ha-yan, staff reporter

Please direct comments or questions to [english@hani.co.kr]

Editorial・opinion

![[Column] Park Geun-hye déjà vu in Yoon Suk-yeol [Column] Park Geun-hye déjà vu in Yoon Suk-yeol](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0424/651713945113788.jpg) [Column] Park Geun-hye déjà vu in Yoon Suk-yeol

[Column] Park Geun-hye déjà vu in Yoon Suk-yeol![[Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent [Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0424/7317139454662664.jpg) [Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent

[Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent- [Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father

- [Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?

- [Editorial] Japan’s rewriting of history with Korea has gone too far

- [Column] The president’s questionable capacity for dialogue

- [Column] Are chaebol firms just pizza pies for families to divvy up as they please?

- [Column] Has Korea, too, crossed the Rubicon on China?

- [Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK

- [Editorial] Does Yoon think the Korean public is wrong?

Most viewed articles

- 1‘We must say no’: Seoul defense chief on Korean, USFK involvement in hypothetical Taiwan crisis

- 2N. Korean delegation’s trip to Iran shows how Pyongyang is leveraging ties with Moscow

- 3‘Weddingflation’ breaks the bank for Korean couples-to-be

- 4Korea sees more deaths than births for 52nd consecutive month in February

- 5[Column] Park Geun-hye déjà vu in Yoon Suk-yeol

- 6Will NewJeans end up collateral damage in internal feud at K-pop juggernaut Hybe?

- 7[Column] Has Korea, too, crossed the Rubicon on China?

- 8Amnesty notes ‘erosion’ of freedom of expression in Korea in annual human rights report

- 9Samsung barricades office as unionized workers strike for better conditions

- 10[Column] The clock is ticking for Korea’s first lady