hankyoreh

Links to other country sites 다른 나라 사이트 링크

Novel coronavirus takes toll on S. Korean SMEs

Following the outbreak of the novel coronavirus, a small South Korean company that makes machinery used to manufacture semiconductors hasn’t been able to export products to China. With its factories on the ground in China currently out of commission, it has to delay shipments of equipment to Chinese buyers that were originally scheduled for the end of February. The company CEO admitted that he’s already having trouble finding funds to keep the company running.

“We think it will take about three months to completely normalize operations at our Chinese partner,” the CEO told the Hankyoreh in a telephone interview on Feb. 10. “We don’t get paid until we ship the equipment, which leaves us under considerable pressure to raise funds.”

On Monday, employees only showed up for work at 20% of the Chinese semiconductor factories that work with this Korean company. Employees are on a two-week self-quarantine after the Chinese New Year, and the Japanese and American engineers who had been handling the equipment are out of the picture, the CEO said.

The CEO of another small company that makes packaging machinery told the Hankyoreh about similar woes. “We’ve had to completely stop manufacturing some of our products.” This company has factories in both China and South Korea, and its Chinese factories produce both products for the Chinese market and parts for Korean factories. But since its Chinese factories aren’t operational, the company can’t make machinery that requires molds located in China. “A single shipping container is enough to hold all the manufactured goods we’re able to bring over in one month,” the CEO sighed.

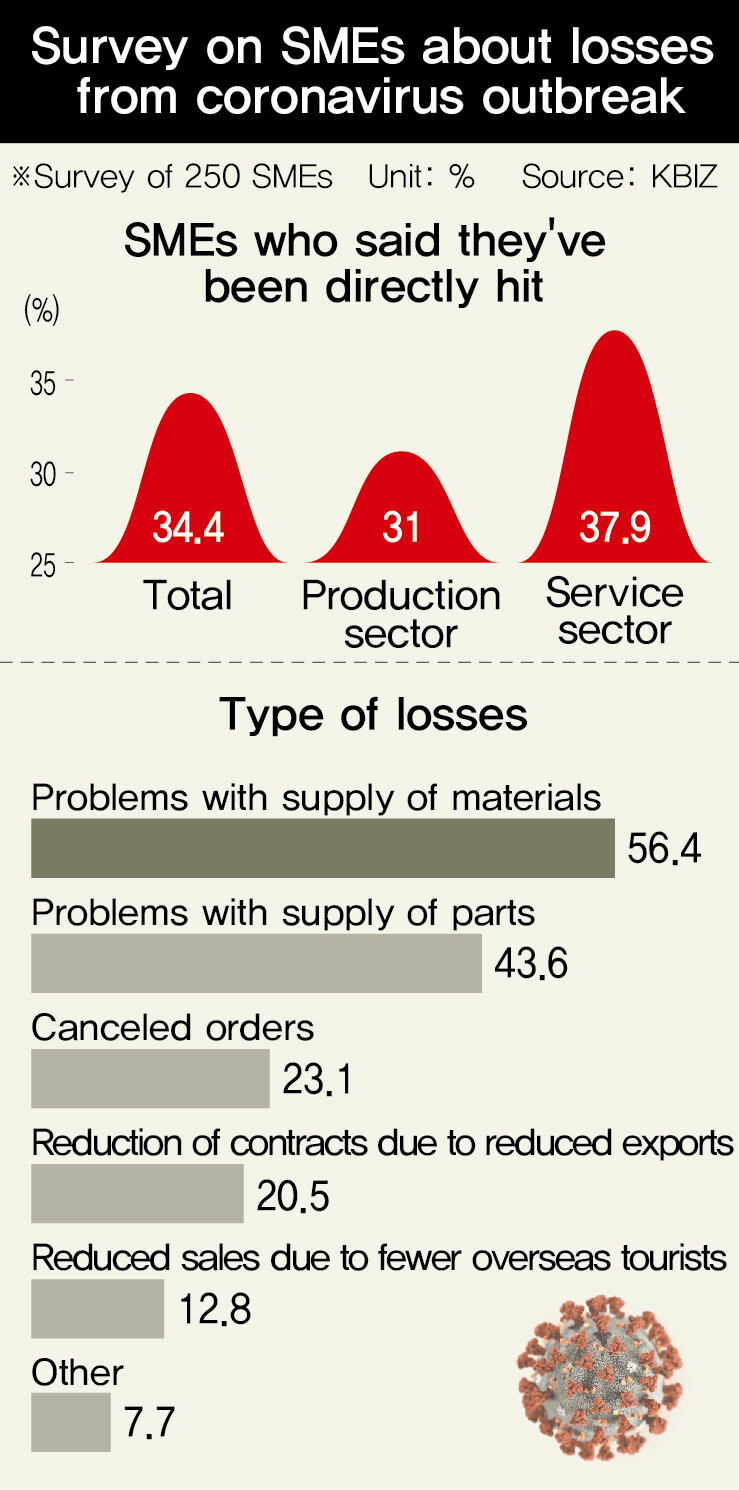

When the Korea Federation of SMEs (KBIZ) asked 250 small and medium-sized enterprises about their opinion of the coronavirus and its impact, 34.4% of the surveyed SMEs said they’d taken a direct hit, and 43.2% said that economic perceptions were worse than before the outbreak. Companies surveyed included companies exporting to or importing from China, companies with local branches in China, and small businesses in the South Korean service sector.

Divided by business category, about three out of 10 (31%) manufacturing firms and about four out of 10 (37.9%) of service sector firms reported seeing losses because of the novel coronavirus outbreak. Worsening economic perceptions were reported by more service sector firms (56.5%) than manufacturing firms (30.2%). The most commonly reported type of damage in the manufacturing sector was the disruption of their supply of raw materials, cited by about six out of 10 companies (56.4%). Less common responses were disruption of their supply of parts (43.6%), cancelled contracts (23.1%), and fewer opportunities to win bids because of cancelled export fairs (20.5%). A whopping 76.6% of companies in the service sector reported experiencing reduced sales because of the falling number of overseas visitors.

The most important measure the government can take in response to the coronavirus outbreak, according to 61.2% of SMEs in the survey, is moving quickly to ease public fears. Other necessary measures include supporting business activity by postponing tariffs and other taxes (50.0%), moving ahead with pump-priming to stimulate the domestic economy (34.8%), and disbursing emergency funds to help affected companies stabilize their business (34.0%).

“The problem is that we’ve been overdependent on China. We’ve been especially reliant for materials, parts, and equipment, and we need to be thinking about [setting up] a new supply chain that localizes production of more of those elements,” said Kim Mun-gyeom, director of the graduate school of entrepreneurship and small business at Soongsil University.

But since the Chinese government has recently instructed factories to resume operations, there’s likely to be considerable improvement in South Korean companies’ production difficulties. According to a document released on Monday by the Ministry of Trade, Industry, and Energy, 27 of the wiring harness factories in China whose operations had been halted through Feb. 5 resumed production on a limited basis on Feb. 9, and China is allowing the resumption of operations at more plants that have finished preparations for disease control. That should help relieve difficulty in sourcing parts, which caused South Korean automakers, including Hyundai and Kia, to temporarily halt operations.

By Kim Yoon-ju and Kim Eun-hyoung, staff reporters

Please direct comments or questions to [english@hani.co.kr]

Editorial・opinion

![[Column] Park Geun-hye déjà vu in Yoon Suk-yeol [Column] Park Geun-hye déjà vu in Yoon Suk-yeol](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0424/651713945113788.jpg) [Column] Park Geun-hye déjà vu in Yoon Suk-yeol

[Column] Park Geun-hye déjà vu in Yoon Suk-yeol![[Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent [Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0424/7317139454662664.jpg) [Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent

[Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent- [Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father

- [Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?

- [Editorial] Japan’s rewriting of history with Korea has gone too far

- [Column] The president’s questionable capacity for dialogue

- [Column] Are chaebol firms just pizza pies for families to divvy up as they please?

- [Column] Has Korea, too, crossed the Rubicon on China?

- [Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK

- [Editorial] Does Yoon think the Korean public is wrong?

Most viewed articles

- 1‘We must say no’: Seoul defense chief on Korean, USFK involvement in hypothetical Taiwan crisis

- 2N. Korean delegation’s trip to Iran shows how Pyongyang is leveraging ties with Moscow

- 3Amnesty notes ‘erosion’ of freedom of expression in Korea in annual human rights report

- 4‘Weddingflation’ breaks the bank for Korean couples-to-be

- 5[Reportage] On US campuses, student risk arrest as they call for divestment from Israel

- 6[Column] Park Geun-hye déjà vu in Yoon Suk-yeol

- 7Korea sees more deaths than births for 52nd consecutive month in February

- 8Will NewJeans end up collateral damage in internal feud at K-pop juggernaut Hybe?

- 9[Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father

- 10[Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent