hankyoreh

Links to other country sites 다른 나라 사이트 링크

[News analysis] Why have Hyundai and Samsung decided to team up on EV batteries?

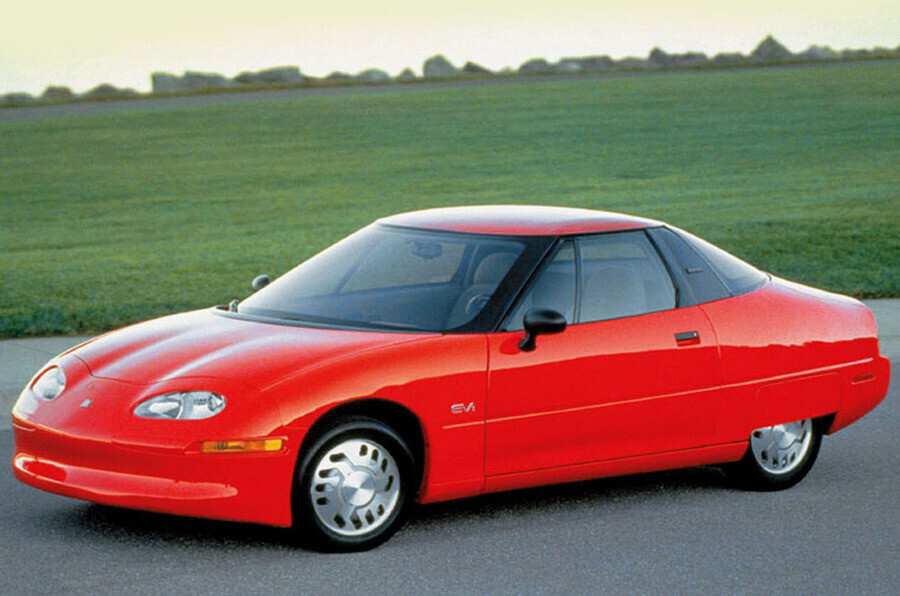

In 2010, there were just 61 electric vehicles (EVs) registered in South Korea. Within four years, that number had increased 20-fold, to 1,308.

Each year since then, the EV total has shot up, to 2,917 in 2015, 5,099 in 2016, and 13,724 in 2017. In 2018, the tally leaped past 50,000, reaching 55,756.

These numbers only count pure EVs that run on batteries; when hybrid and plug-in hybrid vehicles are added in, the number of vehicles sold with an electric powertrain (the component that supplies power to the vehicle) has far exceeded expectations. As EV sales have rapidly risen, so too has interest in batteries. To really understand EVs, one first needs to understand the batteries that serve as a key component in them.

EV batteries broadly consist of a cell, a module, and a pack. The cell, which is the basic part of the battery, needs to possess a high capacity relative to unit volume so that it can achieve maximum performance within the vehicle’s limited space. The battery must have a much longer life than the ones used in ordinary mobile devices. It also needs to withstand the shocks that arise during driving and boast high stability even amid low or high temperatures. Several cells are linked together and placed in a frame to keep them safer amid external sources of shock such as heat and vibrations; this is what is known as a module.

A battery pack combines numerous modules with a battery management system and cooling devices to manage the batteries’ temperature and voltage, among other things. Thousands of battery cells are included in a single pack for an EV.

It would be very incorrect to think of the battery as serving solely as a kind of “fuel tank.” It also plays a similar role to the engine in an internal combustion-based vehicle. The driving distance and maximum motor output are determined by the battery’s capacity and voltage. This means that an EV’s range and performance are decided by battery capacity. But increasing battery capacity to allow vehicles to travel farther and faster is no simple task. The reasons for that have to do with the battery’s volume and weight. A large battery reduces the amount of space as well as energy efficiency. Since a vehicle is a moving product, it also negatively impacts movement performance. So the best way to increase battery capacity is by increasing energy density. A cell has to be small and light while also concentrating electrical energy.

The rechargeable batteries used in EVs come in many different types, including lead-acid batteries, nickel-cadmium batteries, nickel-hydrogen batteries, lithium-ion batteries, and lithium polymer batteries. The most widely used EV battery around the world is the lithium-ion battery. A lithium-ion battery consists of a cathode, electrode, separator, and electrolyte. Electricity is produced as lithium ions move from the electrode to the cathode and vice versa across the liquid electrolyte; this results in energy being released. The biggest advantage of lithium-ion batteries is the absence of a memory effect. When a nickel battery is charged, any remaining amount is “remembered,” resulting in a loss of maximum energy capacity. Since there is no memory effect with lithium-ion batteries, they can be charged along the way without losing capacity.

But lithium metals are temperature-sensitive and risk exploding when kept for too long in high temperatures or strong sunlight. In addition, there are explosion risks associated with the electrolyte solution leaking and causing the lithium transition metal to become exposed to the air, or with overcharging resulting in chemical reactions that cause pressure to rise within the battery. These stability concerns are the reason that Toyota and Lexus use low-energy density nickel metal batteries rather than lithium-ion batteries in their Avalon and Prius vehicles sold in South Korea. To reduce the risk of explosion in the event of a collision, Hyundai Motor devised a quadruple safety system; Jaguar’s I-PACE vehicle is designed with a sealed battery pack and waterproofing to allow it to travel at wade depths of 500 millimeters. While lithium-ion batteries boast many advantages, the liquid state of the electrolyte means that the risk of an explosion in the event of a collision cannot be completely ruled out. This is why the all-solid-state battery has been pointed to as the “next-generation battery.”

All-solid-state batteries were one of the key topics discussed when then Hyundai Motor Group Senior Vice Chairman (current Chairman) Chung Eui-sun met with Samsung Electronics Vice Chairman Lee Jae-yong on May 13. The two of them share the same target in terms of seizing the advantage in the future EV market: Lee is developing an all-solid-state battery, and Chung is acquiring it. Using a solid rather than a liquid electrolyte, the all-solid-state battery boasts structural solidity and stability that remove the risk of explosions or fires.

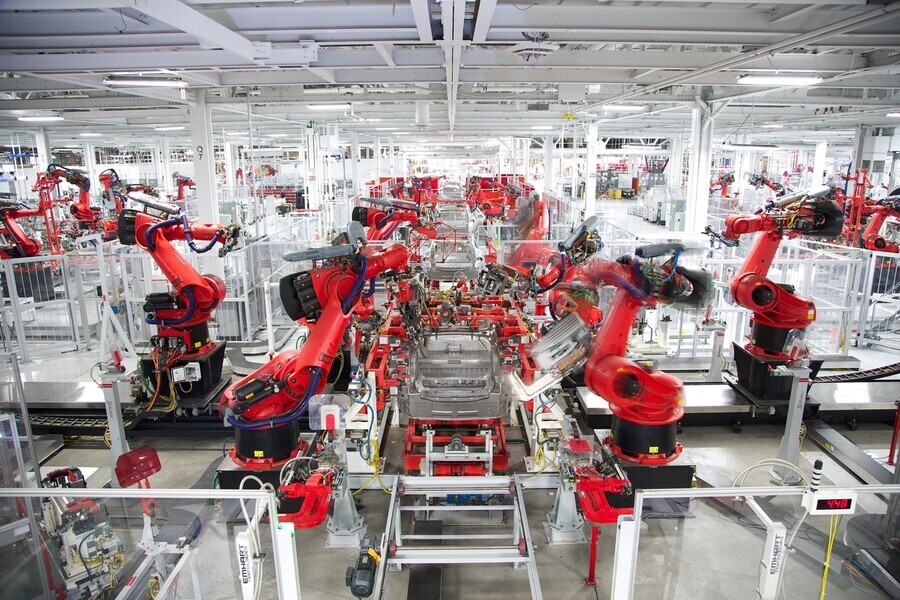

The batteries can be filled with active material that increases capacity while obviating the need for safety components -- meaning that the spatial use efficiency and energy density are that high. No separator is needed, which means the batteries can be produced in different forms such as thin and bendable ones. Tesla, a company that has become synonymous with EVs, is currently using a lithium-ion battery. The batteries produced by LG Chem are lithium-ion and lithium polymer batteries. Hyundai Motor primarily uses lithium polymer batteries, but once Samsung SDI succeeds in producing an all-solid-state battery, it hopes to acquire those volumes to secure an advantage in the global EV market.

Another reason for the growing interest in all-solid-state batteries is the increased use of autonomous vehicles (AVs). As AVs become more advanced, they require high-capacity batteries to cope with the power consumption associated with data processing. According to the software company Tuxera, an AV uses an average of around 11 terabytes (TB) of data per day. To get a sense of how enormous that amount is, consider that a semiconductor factory the size of four soccer fields uses 45TB of data a day. Also, an EV with an all-solid-state battery could theoretically run for over 800 kilometers on a single charge -- twice the distance for a current lithium-ion battery. One more reason that people are looking forward to all-solid-state batteries concerns the charging time. Five minutes would be enough time to achieve an 80% charge -- roughly the same amount of time currently needed to fill up a gasoline or diesel vehicle.

In the era of internal combustion, automobile makers developed and produced their own engines, the core parts of the vehicle. But the EV era is different. Automobile makers do not produce their batteries, but acquire them from battery makers. The fact that such an important component has to be supplied seems to suggest that leadership in the future vehicle market could shift from the automobile makers to the battery makers.

By Kim Sun-kwan, editor of Motor Trend

Please direct comments or questions to [english@hani.co.kr]

Editorial・opinion

![[Column] Season 2 of special prosecutor probe may be coming to Korea soon [Column] Season 2 of special prosecutor probe may be coming to Korea soon](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0426/3317141030699447.jpg) [Column] Season 2 of special prosecutor probe may be coming to Korea soon

[Column] Season 2 of special prosecutor probe may be coming to Korea soon![[Column] Park Geun-hye déjà vu in Yoon Suk-yeol [Column] Park Geun-hye déjà vu in Yoon Suk-yeol](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0424/651713945113788.jpg) [Column] Park Geun-hye déjà vu in Yoon Suk-yeol

[Column] Park Geun-hye déjà vu in Yoon Suk-yeol- [Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent

- [Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father

- [Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?

- [Editorial] Japan’s rewriting of history with Korea has gone too far

- [Column] The president’s questionable capacity for dialogue

- [Column] Are chaebol firms just pizza pies for families to divvy up as they please?

- [Column] Has Korea, too, crossed the Rubicon on China?

- [Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK

Most viewed articles

- 1‘We must say no’: Seoul defense chief on Korean, USFK involvement in hypothetical Taiwan crisis

- 2N. Korean delegation’s trip to Iran shows how Pyongyang is leveraging ties with Moscow

- 3[Column] Season 2 of special prosecutor probe may be coming to Korea soon

- 4‘Weddingflation’ breaks the bank for Korean couples-to-be

- 5[Column] Has Korea, too, crossed the Rubicon on China?

- 6[Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent

- 7[Reportage] On US campuses, student risk arrest as they call for divestment from Israel

- 8Korea sees more deaths than births for 52nd consecutive month in February

- 9[Column] Park Geun-hye déjà vu in Yoon Suk-yeol

- 10[Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father