hankyoreh

Links to other country sites 다른 나라 사이트 링크

Recently extended nuke reactor doesn’t meet safety standards

[%%IMAGE2%%]

After the South Korean government approved an extension of the lifespan for Wolseong Nuclear Power Plant reactor 1 on Feb. 27, activist groups are arguing that the reactor does meet the latest safety standards of the International Atomic Energy Agency (IAEA).

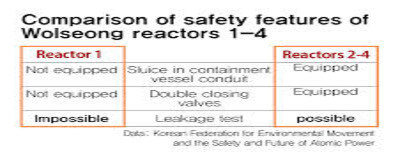

“Unlike reactors no. 2, no. 3, and no. 4 at Wolseong, the containment vessel at reactor no. 1 does not have a sluice in the conduit that is used to remove used nuclear fuel. As a result, it cannot carry out the leak test required by the International Atomic Energy Agency and thus does not satisfy the international standards for safety inspection,” the Korean Federation for Environmental Movement and the Safety and Future of Atomic Power, an organization of atomic power experts, said on Mar. 4.

Twice a day for 40 minutes at a time, spent nuclear fuel is removed from the containment vessels at the first four reactors at Wolseong. The containment vessels contain the CANada Deuterium Uranium (CANDU) heavy water reactors used at the plant.

In 1991, the Canadian nuclear safety authorities strengthened the R-7 standards in order to reinforce the equipment that keeps radiation from leaking out of the containment vessel while spent fuel is being removed. The revised standards require that a sluice be placed on the water tank that the spent fuel is released from and that double closing valves be installed.

Sluices and double closing valves were installed on Wolseong reactors no. 2, no. 3, and no. 4 according to these revised standards, but they were not applied to reactor no. 1, which had an earlier design.

“We created our own standards, based on foreign standards, and have carried out radiation leak tests every five years. During our review of the proposal to keep running the reactor, we examined the results of these tests and confirmed that there were no issues,” said the Korea Institute of Nuclear Safety, which reviewed the proposal to extend the lifespan at reactor no. 1.

But Lee Jeong-yun, president of Safety and Future of Atomic Power, said, “The enforcement decree of the Nuclear Safety Act states that, for the lifespan of a nuclear reactor to be extended, the reactor must be upgraded so that it satisfies the latest safety standards. According to the 2012 standards by the International Atomic Energy Agency, which are the latest standards, Wolseong Reactor 1 cannot even carry out a radiation leak test”.

The measure described in the Canadian standards is conducting a leak test at a pressure that is lower than the design pressure and then mathematically convert this to design pressure conditions. But after the Fukushima nuclear disaster in 2011, the IAEA tightened up the regulations, requiring reactors to conduct a leak test at the actual design pressure.

Design pressure refers to the greatest pressure that the reactor designers expect the containment vessel might endure during an accident.

Since there is no sluice at Wolseong reactor 1, if a leak test is carried out at the design pressure of 18psig, the 3.5 cubic meters of water in the tank would all leak, since the water can only withstand 5 pounds per square inch of pressure. This means that no test can be carried out to determine whether the radiation might be leaking.

By Lee Geun-young, senior staff writer

Please direct questions or comments to [english@hani.co.kr]

Editorial・opinion

![[Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces [Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0416/8917132552387962.jpg) [Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces

[Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces![[Editorial] 10 years on, lessons of Sewol tragedy must never be forgotten [Editorial] 10 years on, lessons of Sewol tragedy must never be forgotten](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0416/8317132536568958.jpg) [Editorial] 10 years on, lessons of Sewol tragedy must never be forgotten

[Editorial] 10 years on, lessons of Sewol tragedy must never be forgotten- [Column] A death blow to Korea’s prosecutor politics

- [Correspondent’s column] The US and the end of Japanese pacifism

- [Guest essay] How Korea turned its trainee doctors into monsters

- [Guest essay] As someone who helped forge Seoul-Moscow ties, their status today troubles me

- [Editorial] Koreans sent a loud and clear message to Yoon

- [Column] In Korea’s midterm elections, it’s time for accountability

- [Guest essay] At only 26, I’ve seen 4 wars in my home of Gaza

- [Column] Syngman Rhee’s bloody legacy in Jeju

Most viewed articles

- 1[Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces

- 2[Guest essay] How Korea turned its trainee doctors into monsters

- 3Faith the power of memory: Why these teens carry yellow ribbons for Sewol

- 4[Editorial] 10 years on, lessons of Sewol tragedy must never be forgotten

- 5[News analysis] Watershed augmentation of US-Japan alliance to put Korea’s diplomacy to the test

- 6US grants Samsung up to $6.4B in subsidies for its chip investments there

- 7How Samsung’s promises of cutting-edge tech won US semiconductor grants on par with TSMC

- 8‘National emergency’: Why Korean voters handed 192 seats to opposition parties

- 9Korea ranks among 10 countries going backward on coal power, report shows

- 10[Column] A death blow to Korea’s prosecutor politics