hankyoreh

Links to other country sites 다른 나라 사이트 링크

After a drunken peak, makgeolli’s 3 year hangover

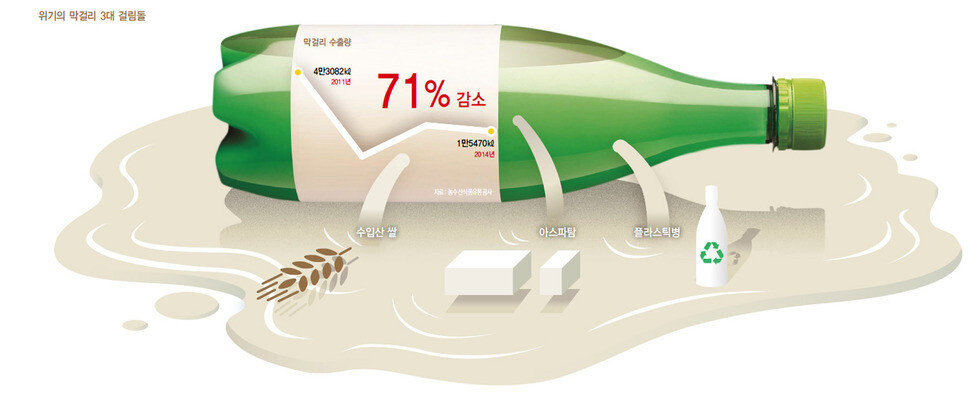

Five years ago, the makgeolli industry was drunk on itself. Today it lacks the energy it once had. The makgeolli boom began in 2009 and by 2011 production amounts, sales, and exports reached the highest points in history. After 2012, the makgeolli market began declining. Exports fell from 458,198kl in 2011 to 426,216kl in 2013, and sales decreased from around 509.7 billion won ($466.4 million) in 2011 to around 473.8 billion won ($433.1 million) in 2013, declines of 7%. Exports decreased from 43,082kl in 2011 to 15,470kl in 2014, while export revenue plummeted from $52,730,000 to $15,350,000.

Of course, compared to before 2008, when makgeolli output was less than 200,000kl and sales were less than 200 billion won (US$182.8 million), current output and sales have doubled. The problem is that while there are 900 manufacturers listed nationwide and makgeolli has great growth potential with sales making up 5-6 percent of the entire alcohol market, the makgeolli market is shrinking. Furthermore, during the last few years with foreign wine and beer flooding into South Korea, the ground for makgeolli to develop has been undermined by the craft beer explosion.

Brewing specialists say that makgeolli made by contemporary methods has reached its growth limit. They advise that if makgeolli is going to break free from its post-2011 stagnancy, three obstacles must be overcome: the use of imported rice, the use of aspartame and other sweeteners, and the use of plastic bottles. The way to simply resolve these three problems is to raise the price of makgeolli. Herein lies the concern of makgeolli breweries.

Domestic rice vs. imported riceThe makgeolli industry’s most debated problem is the use of imported rice. Jangsu Makgeolli, the top-selling product of Korea’s largest makgeolli company, Seoul Takju, is made in large part with imported rice. (‘Takju’ is another word for makgeolli.) If you include Seoul Takju’s premium products, such as Jang Makgeolli, the amount of imported rice is still over 80 percent. Takju’s brewery companies in Busan, Incheon, Daegu, Jeju, and Gwangju- uses over 90% imported rice. Of the top ten companies with the highest makgeolli sales, Kooksoondang uses the highest portion of domestic rice, at 70 percent.

Costs are the reason for the high portion of imported rice. For makgeolli production between 2010 and 2012, the price of 40kg of domestic rice ranged from 63,700 won ($58.49) to 81,900 won ($75.21), 2.3-3.7 times higher than imported rice (22,090 won-28,200 won, $20.29-$25.89). Because rice is the largest expense in makgeolli production, using domestic rice instantly increases the price of makgeolli.

Experts pointed out that the uniqueness and locality of makgeolli’s ingredients are essential elements if the drink is to receive positive attention. Hur Shi-myung, principal of the Makgeolli School, said that, “French Bordeaux wine must use Bordeaux grapes. Japanese sake must use Japanese rice. It is difficult to make an identity or style for a makgeolli made with imported rice.”

Therefore, nowadays breweries making premium makgeolli are focusing on using domestically grown rice. Eleven out of thirteen of Kooksoondang’s makgeollis are brewed with domestic rice. The sister company, Baesangmyeon Brewery makes three makgeollis, all using domestic rice. Recently, the small-scale breweries that are receiving attention primarily use domestic rice. However, they still only represent a small portion of the whole market. Seoul Takju uses 80% imported rice, but Jang Makgeolli and Ee:FF Makgeolli, like high quality makgeollis, uses domestic rice.

No sweeteners vs. aspartame

The most deadly element to makgeolli’s flavor are aspartame and other chemical sweeteners. Controversy once surrounded aspartame’s health effects, but the Ministry of Food and Drug Safety has since recognized it as a safe food additive. Even though it may not be toxic, some argue that that aspartame erases the individuality of various makgeollis during production. Aspartame makes makgeollis all taste the same.

There is also a counter argument. Nam Do-hee, director of the Korean Makgeolli Association said, “Using aspartame is the easiest and best way to make a consistent flavored makgeolli for breweries.” Another opinion is that the palette of contemporary Koreans has been conditioned to sweet things.

Lee Chang-yong, Seoul Takju’s assistant manager, said, “It is difficult for contemporary Koreans to drink makgeolli that wasn’t made with aspartame. Even using small quantities of traditional nuruk [a wheat-based fermentation starter] raise dissatisfaction that the drink has a musty odor.”

Cho Hyo-jin, head professor at Susubori Academy, said, “Aspartame is the only option if you want to make a quick, sweet makgeolli using cheap imported rice. By using lots of good rice and slowly fermenting, it is possible to make makgeolli sweet without using aspartame.”

Makgeollis that don’t use sweeteners are very rare. Of large-scale makgeolli, Baesangmyeon Brewery’s Slow Village Makgeolli (Nurin Maeul in Korean), and of small-scale makgeolli, Song Myung-Sup Makgeolli, are two notable examples. Kooksoondang’s Yetnal Makgeolli (“Old Fashioned Makgeolli”) does not use aspartame, but instead uses fructose.

Glass bottle vs. plastic bottle

The issue of plastic bottles being used for containers continues to cause controversy. Plastic bottles receive low marks due to their health and environmental impact, and their “dignity.” The design of the plastic makgeolli bottle has secured its universality, but the quality of the plastic and the excessive container size (750ml) still cause controversy.

The reason for using plastic bottles is to minimize costs. According to the Korea Takyakju Production Association, the cost of a 750ml plastic bottle is 125 won ($0.11), while a smaller, 500ml glass bottle costs 750 won ($0.69), 6 times as much. It is impossible to dream of using glass bottles because generally one bottle of makgeolli is only 1,000 won ($.92). It would be possible to use glass bottles because they can be recycled, but makgeolli sales are small and the majority of breweries are small-scale so it would not be easy. Unlike pasteurized makgeolli, fresh makgeolli continues to ferment during distribution so it is difficult to use airtight bottles.

From May to October, the Takju and Yakju Central Association and the Korean Makgeolli Association are holding a public contest to design new glass makgeolli bottles and cups. Major factors will include using glass bottles, decreasing the size of the container, and new designs.

[%%IMAGE5%%]2,000 won price vs. 1,000 won price

Industry experts say that these three obstacles originate from the price of makgeolli being just over 1,000 won. In order to manage the costs of using domestic rice and not using aspartame, the price of one bottle of makgeolli has to rise to over 2,000 won ($1.83). This can be seen in the cases of Kooksoondang’s Yetnal Makgeolli and Baesangmyeon Brewery’s Slow Village Makgeolli, both around 2,500 won ($2.29). Of course, if these makgeollis were put in glass bottles the price would jump to 3,000 won ($2.75).

The makgeolli industry feels that prices cannot easily rise. Shin Mi-hwa, department head of Takyakju Central Association says that, “A 1,000 won bottle of alcohol is very cheap, but the makgeolli market is sensitive. Makgeolli consumers have strongly chosen the side of a low quality and inexpensive product.”

Go Bong-han, Kooksoondang’s team leader, says, “We released ‘Yetnal Makgeolli’ with a retail price of 2,000 won, but it is currently sold more for household consumption than for restaurants or bars. Makgeolli is still widely recognized as a cheap alcohol.”

Bae Young-ho, CEO of Baesangmyeon Brewery, says that, “Beer has advanced from imported beer to the point of small-scale, housebrews. Consumers are looking for good drinks, but makgeolli producers persist in making a 1,000 won cheap product.”

Professor, Cho Hyo-jin, says, “Small-scale breweries make cheap drinks with cheap ingredients. Technology and quality improvements never occur. Domestic drinks are stuck in a low cost market, surrendering the middle and higher-end to foreign drinks.”

By Kim Kyu-won, staff reporter

Translated by Dan Sizer, Hankyoreh English intern

Please direct questions or comments to [english@hani.co.kr]

Editorial・opinion

![[Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father [Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0423/8317138574257878.jpg) [Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father

[Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father![[Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms? [Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0423/3617138579390322.jpg) [Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?

[Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?- [Editorial] Japan’s rewriting of history with Korea has gone too far

- [Column] The president’s questionable capacity for dialogue

- [Column] Are chaebol firms just pizza pies for families to divvy up as they please?

- [Column] Has Korea, too, crossed the Rubicon on China?

- [Correspondent’s column] In Japan’s alliance with US, echoes of its past alliances with UK

- [Editorial] Does Yoon think the Korean public is wrong?

- [Editorial] As it bolsters its alliance with US, Japan must be accountable for past

- [Guest essay] Amending the Constitution is Yoon’s key to leaving office in public’s good graces

Most viewed articles

- 1Samsung barricades office as unionized workers strike for better conditions

- 2[Editorial] Japan’s rewriting of history with Korea has gone too far

- 3[Column] The clock is ticking for Korea’s first lady

- 4[Column] The president’s questionable capacity for dialogue

- 5[Reporter’s notebook] Did playing favorites with US, Japan fail to earn Yoon a G7 summit invite?

- 6Korean government’s compromise plan for medical reform swiftly rejected by doctors

- 7Why Korea shouldn’t welcome Japan’s newly beefed up defense cooperation with US

- 8Senior doctors cut hours, prepare to resign as government refuses to scrap medical reform plan

- 9[Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?

- 10[Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father