hankyoreh

Links to other country sites 다른 나라 사이트 링크

Airless tires may be in market next year for bicycles

Many of the new products and technology that have become so useful to our lives today emerged out of the space technology development process. Examples include microwave ovens, memory foam, LASIK surgery, home water purifiers, sunglasses, freeze-dried foods and cordless power tools.

According to NASA, over 2,000 forms of space technology have been put to use in earthbound products and technologies since 1976.

Now one more example of commercialized space technology has been added to the list: airless tires.

A startup calling itself the SMART Tire Company has made plans to market airless tires for bicycles, using NASA space probe technology to develop tires that are elastic like rubber with the strength of titanium.

Known as “METL,” the tire material is Nitinol, a nickel-titanium alloy with shape memory properties. Tires made with this alloy are heated to temperatures of over 500°C and then rapidly cooled to give them the “memory” that allows them to immediately regain their original shape when it is altered.

The company claims that the tires produced by arranging this memory alloy in a radial shape have a resilience 30 times stronger than steel. This means that they do not need to be inflated like ordinary rubber tires, nor is there any risk of going flat.

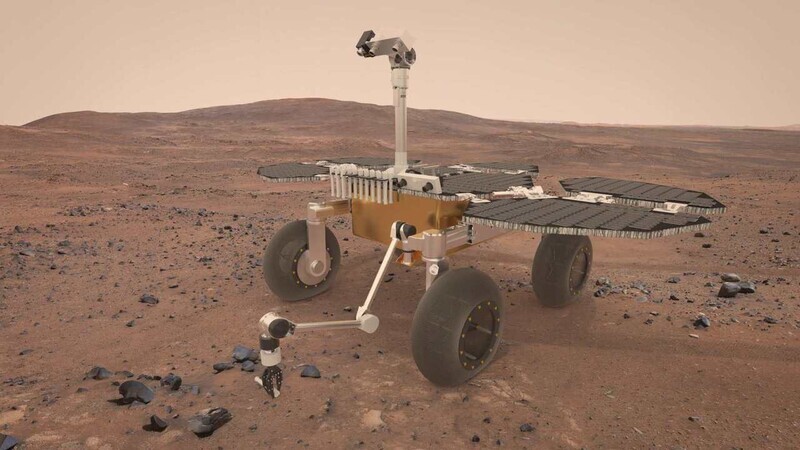

The technology was developed by researchers at the NASA Glenn Research Center for use on Mars rovers in a process that lasted over a decade and cost some US$10 million.

The current rovers have wheels made with aluminum materials and streamlined titanium spokes to retain some elasticity. NASA has said that the new tires could allow the number of wheels on Mars and moon rovers to be reduced from six to four.

NASA plans to use the new tires on a Mars rover to be deployed in 2026.

It was through a technology transfer program administered by NASA that this technology became available for a private company to use. The program’s aim is to further the national interest through the development of NASA technology into innovative products that can be widely used by the general public.

Last year, the SMART Tire Company signed an agreement with NASA toward the commercialization of the technology. It is now raising investments to build mass production facilities, with the aim of having a bicycle tire on the market sometime next year.

It plans to focus first on tires for bicycles, motorcycles and other two-wheeled vehicles before eventually branching out into tires for cars and trucks.

The SMART Tire Company says the shape memory alloy tires last longer and can withstand heavier loads than ordinary rubber tires. A single tire can bear a weight of 20,000 pounds (9 tons), and the weight of a jet aircraft can be reduced by hundreds of kilograms with the use of the tires for its landing gear.

As another advantage of its airless tires, the company said they obviate environmental pollution concerns by rubber tires.

According to the SMART Tire Company, as much as 23 million tons of rubber tire waste is generated worldwide in a year. Most of these waste tires are either landfilled or incinerated in open-air yards, resulting in environmental pollution.

Tires are also a major source of microplastic. Between 20% and 30% of the microplastic in the oceans is believed to come from tires.

This is not the first tire to be developed that does not require inflation. In 2019, Michelin unveiled a prototype for an airless tire known as the Uptis. Its target is to market the tires for cars and compact SUVs by 2024.

Tires using air forced into a rubber tube first appeared in the 19th century. Over the course of the 20th century, their performance capabilities were enhanced with the development of tread tires, radial tires and run-flat tires.

During the 21st century, electric vehicles have come to replace internal combustion engine vehicles due to their greater eco-friendliness. Many are now watching to see whether a similar situation happens with tires as shape memory tires come to replace rubber ones that rely on air pressure.

The global tire market is believed to amount to some US$250 billion, including tires for bicycles, motorcycles, cars, trucks and aircraft.

By Kwak No-pil, senior staff writer

Please direct comments or questions to [english@hani.co.kr]

Editorial・opinion

![[Editorial] Penalties for airing allegations against Korea’s first lady endanger free press [Editorial] Penalties for airing allegations against Korea’s first lady endanger free press](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/original/2024/0502/1817146398095106.jpg) [Editorial] Penalties for airing allegations against Korea’s first lady endanger free press

[Editorial] Penalties for airing allegations against Korea’s first lady endanger free press![[Editorial] Yoon must halt procurement of SM-3 interceptor missiles [Editorial] Yoon must halt procurement of SM-3 interceptor missiles](https://flexible.img.hani.co.kr/flexible/normal/500/300/imgdb/child/2024/0501/17145495551605_1717145495195344.jpg) [Editorial] Yoon must halt procurement of SM-3 interceptor missiles

[Editorial] Yoon must halt procurement of SM-3 interceptor missiles- [Guest essay] Maybe Korea’s rapid population decline is an opportunity, not a crisis

- [Column] Can Yoon steer diplomacy with Russia, China back on track?

- [Column] Season 2 of special prosecutor probe may be coming to Korea soon

- [Column] Park Geun-hye déjà vu in Yoon Suk-yeol

- [Editorial] New weight of N. Korea’s nuclear threats makes dialogue all the more urgent

- [Guest essay] The real reason Korea’s new right wants to dub Rhee a founding father

- [Column] ‘Choson’: Is it time we start referring to N. Korea in its own terms?

- [Editorial] Japan’s rewriting of history with Korea has gone too far

Most viewed articles

- 1Months and months of overdue wages are pushing migrant workers in Korea into debt

- 2Trump asks why US would defend Korea, hints at hiking Seoul’s defense cost burden

- 31 in 3 S. Korean security experts support nuclear armament, CSIS finds

- 4[Editorial] Yoon must halt procurement of SM-3 interceptor missiles

- 5[Guest essay] Maybe Korea’s rapid population decline is an opportunity, not a crisis

- 6Fruitless Yoon-Lee summit inflames partisan tensions in Korea

- 7[Column] Can Yoon steer diplomacy with Russia, China back on track?

- 8At heart of West’s handwringing over Chinese ‘overcapacity,’ a battle to lead key future industries

- 9South Korea officially an aged society just 17 years after becoming aging society

- 10Under conservative chief, Korea’s TRC brands teenage wartime massacre victims as traitors